Delta Industries is now an authorized distributor for Pioneer Pump products, a Franklin Electric Company! These products can be viewed in the “Products” tab on our home page or at www.pioneerpump.com.

In addition, we are also very excited about becoming a distributor for the Edwards Vacuum pump line of high-end products from the Atlas Copco Group.

www.edwardsvacuum.com

Our Ampco ZP1 or ZP2 series is 100% interchangeable with a SPX Waukesha U1 or U2 pump as well as other like brands. This includes parts, performance, and dimensions., Call us if you like to save money!

Delta can also perform a complete rebuild of your existing pump regardless of brand.

Stay tuned, We may be taking on a couple of new lines!

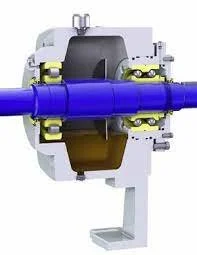

Sulzer offers exchange bearing fame replacements under their “BUX” (Bearing Unit eXchange) program which means, you send us your old worn-out bearing frame and we will sell you a new replacement at a considerably reduced price when the replacement core is received. You can’t lose on this deal!

Sulzer Corporation is pleased to inform you that new SDGP (Sulzer degassing pumps) are released for sales. New pump series will replace previously used AHF and MCDP degassing pump series.

We wanted to harmonize our vacuum pump offering and designed the new SDGP pump series which includes 3 sizes: SDGP2-50, SDGP3-50, SDGP6-65.

Degassing pumps are used mainly with MC-Products in MDS Degassing systems and as External Degassing system with AHLSTAR Process Pumps. SDGP pumps can be sold either as a part of the degassing system or individually as replacement spare part.

New SDGP pump series is improved, robust and reliable construction. Design is fully metric and the pumps are made in Duplex Stainless Steel material (41).

There are a few configuration options to fulfill customer needs:

- Coupling type: Normex G or Rex Viva V

- Foundation bolt type: Grouted or welded

- Baseplate surface treatment: ZnK as standard, C4 or C5 painting options

- Optional instrumentation (eCOSP): Pt100 bearing temperature sensors or Sulzer Sense

wireless condition monitoring unit

Sulzer offer a unique stye galvanized pump base that is simple, solid and a cost savings for new construction. The “Three Point Base” is a steel design that is engineered to be cemented in a concrete base foundation offering exact bolt hole locations for pump, motor and guard.

EZSTRIP™ TRANSFER PUMP

For the newest iteration of our EZstrip™ maintain-in-place progressing cavity pump we designed new features to make maintenance even more user friendly than before. In addition to our patented split suction chamber we’ve removed the tie bars, designed a new positive torque split coupling rod, and added in a captive support foot. That means faster, easier maintenance for you. The EZstrip has been specifically designed to provide a quick and easy way to disassemble, de-rag and maintain a PC pump in-situ, eliminating the costly maintenance and down time that servicing can often cause.

Features

Patented split coupling allows full removal of the drive train in minutes with no electrical disconnection required

Pre-assembled drive train available with 2-year warranty to allow faster reassembly time

Suction and discharge ports remain connected to the pipe work

Operational parameters are unaffected since design has no effect on flow and pressure

Low running speeds reduces wear for a longer working pump life; ideal for abrasive applications

Stainless steel cast components and fasteners provide corrosion resistance making them suitable for a variety of applications

SURGE SUPPRESSORS

Versamatic’s diaphragm pump surge suppressors virtually eliminate undesirable pulsation from pumping, as well as provide virtually pulse-free discharge flow for steadier pressure with less system vibration and noise. Delivering steadier pressure that is easier on your piping system, Versamatic surge suppressors are worry-free upon installation and:

Offer outstanding surge suppression: Regardless of pump pressure, they automatically maintain a constant volume of air to dampen pulsations.

Self-charge and self-vent: This promotes ease of use and maximum efficiency.

Have less system vibration and noise: Reduces piping system wear and tear.

Provide chemical compatibility: Available in a variety of sizes and materials.

Are easy to install: Their simple installation makes them the efficient, hassle-free choice.

CONVENIENT, DURABLE & PORTABLE CENTRIFUGAL PUMP

Remove water quickly and easily with the Versamatic PortaPump. The centrifugal PortaPump is rugged, submersible and conveniently operates using any common 12-volt vehicle battery. These dewatering pumps come equipped with 30-foot cables and battery clips or a two-pole connector (-APP). Additionally, these centrifugal pumps are portable, weighing only 33 pounds (15 kg) and fit through openings as small as 10" (25 cm). They feature an external switch to turn on and off, and a rock screen to prevent large particulate from entering the pump.

Applications

Construction

Municipalities and utilities

Plumbing maintenance

Landscaping and irrigation

Cemetery maintenance

Golf course maintenance

SPECIFICATIONS

Flow Rate0-43 gpm (0-163 lpm)Port Size

Discharge

1 1/2" NPT (BSP)

Shipping Weight

Aluminum

33 lbs (15 kg)

Hidrostal Prerostal Matched Flow and Clean Wet-Wells

A method of matching pump outflow to pump station inflow without the need for additional flow control or additional electrical equipment such as inverter drives. A highly effective sump cleaning system without the need for any additional mechanical or electrical items, such as grinders, bar screens oder mixers.

AIR-DRIVEN HIGH-FLOW CENTRIFUGAL PUMP

When your specialty pump application calls for mud, trash, or fast dewatering, the air-driven SludgeMaster centrifugal pump delivers. This centrifugal pump provides the highest flow rates of any of our pumps—up to 300 gpm (1,136 lpm)—and safely operates on compressed air and in areas when electric power is unavailable.

VERSATILE PUMPING SOLUTIONS

Fully submersible

Weighs 59 pounds (27 kg)

Won’t choke on small trash

Can run dry without damage

Handles solids up to 1 ½" (38mm)

Self-draining to prevent damage in subfreezing weather

Fits in openings as small as 14" (0.36 m) diameter

Self-priming

Optional rock screen for ½" (13mm) solids available

Fool-proof design that handles abrasive substances with less wear

Built for rough handling and long life

SLUDGEMASTER CENTRIFUGAL PUMPING APPLICATIONS

Construction

Mining (drift or face dewatering)

Steel mills (sump or quench tanks)

New from Franklin Electric, the MINETUFF series of submersible pumps.

Delta Industries Inc. is very excited to announce that Tim Hanke has joined the team as our new Industrial Salesman. Tim will be covering the lower end of the Washington territory from the Columbia River up to Chehalis.

Tim can be found on LinkedIn.